Last year, maPlatine hosted the Clearaudio team for an amazing event. A few weeks ago, we went to their head office to visit the production plant.

Tour of the Clearaudio site

Clearaudio is based in Germany in Erlangen, northern Bavaria. Erlangen and Rennes have been twin towns since 1964. This is a sign that maPlatine.com and Clearaudio were meant to meet and get on! Our guide during the tour was Clearaudio’s CEO, Robert Suchy. Philippe and Jérôme from Hamy Sound (the French importers) also came along. We were greeted with a warm welcome =)

Clearaudio’s showroom

Our visit started with the showroom where most of the products are on display.  (1) Clearaudio’s prestigious turntables take place of pride on a small platform: the Master Innovation vinyl turntable, the Statement and Innovation vinyl turntable. They are simply amazing! (2) This part of the room is like a museum! (3) On this photo, we can admire the Clearaudio Concept vinyl turntables, as well as the prototypes of tube preamplifiers, headphone amps, etc. The wooden shrine conceals the Absolute Phono phono preamplifier. (4) We also had the opportunity to admire a ‘small’ portion of the Suchy family’s vinyl record collection! The rest takes up several rooms in another part of the plant.

(1) Clearaudio’s prestigious turntables take place of pride on a small platform: the Master Innovation vinyl turntable, the Statement and Innovation vinyl turntable. They are simply amazing! (2) This part of the room is like a museum! (3) On this photo, we can admire the Clearaudio Concept vinyl turntables, as well as the prototypes of tube preamplifiers, headphone amps, etc. The wooden shrine conceals the Absolute Phono phono preamplifier. (4) We also had the opportunity to admire a ‘small’ portion of the Suchy family’s vinyl record collection! The rest takes up several rooms in another part of the plant.

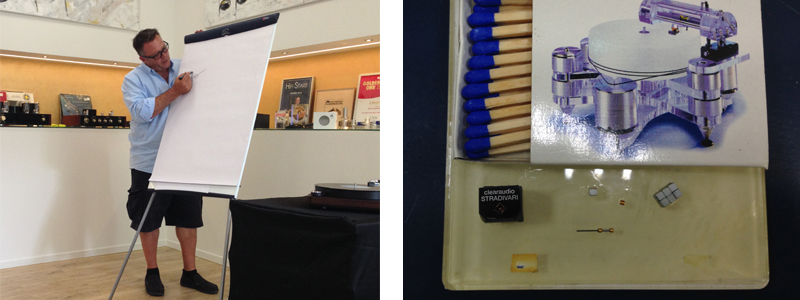

Production of Clearaudio Hi-Fi cartridges

We took part in a training session on the production of Hi-Fi cartridges of the German brand Clearaudio, by Robert Suchy himself. The Clearaudio phono cartridges have several specific technical features. They use twice as many magnets than traditional MC cartridges. Instead of 4, they have at least 8.  On the picture on the right, you can see the various elements that make up the Clearaudio Stradivari MC cartridge (cantilever, stylus, magnets, coils, etc.). On this scaled photo, you can also see the microscopic size of the elements in an MC cartridge. We also took a close look at a very impressive phono cartridge: the Clearaudio Goldfinger Statement MC cartridge. It has a fine 24 carat gold plating and half a carat Swarovski diamond… A real little gem by Clearaudio!

On the picture on the right, you can see the various elements that make up the Clearaudio Stradivari MC cartridge (cantilever, stylus, magnets, coils, etc.). On this scaled photo, you can also see the microscopic size of the elements in an MC cartridge. We also took a close look at a very impressive phono cartridge: the Clearaudio Goldfinger Statement MC cartridge. It has a fine 24 carat gold plating and half a carat Swarovski diamond… A real little gem by Clearaudio!

Production of Clearaudio vinyl turntables

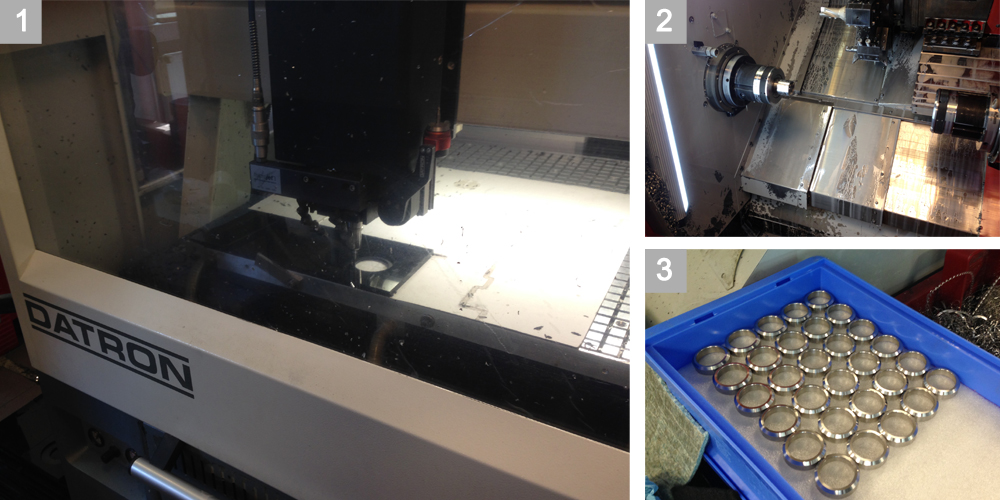

Machining of parts for Clearaudio vinyl turntable

Clearaudio has invested in machines to work on a variety of materials: Bakelite, steel and aluminium. One of those (1) produces 90% of the parts machined in the plant. The machining process for a new part takes up to 7 days to adjust and set up the machines!  (2) This other machine can produce various aluminium and steel parts. For example, the aluminium parts above (3). The plinths of the vinyl turntables produced by Clearaudio also have distinctive features.

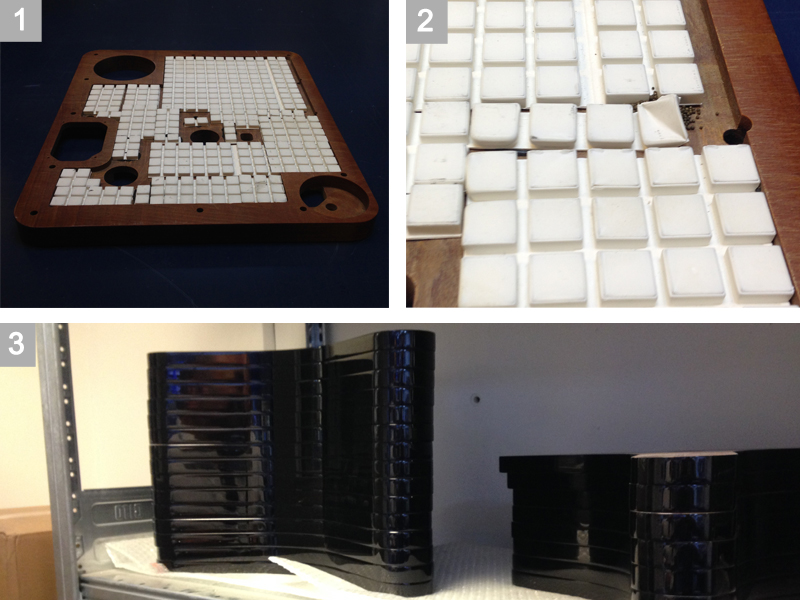

(2) This other machine can produce various aluminium and steel parts. For example, the aluminium parts above (3). The plinths of the vinyl turntables produced by Clearaudio also have distinctive features.  (1) The base of the Concept vinyl turntable features small white cubes with small lead balls (2). They add weight and reduce mechanical vibrations and colourations. (3) The plinth of the Clearaudio Innovation turntables is made out of very hard and expensive wood: PanzerWood! It is even believed to be bulletproof…

(1) The base of the Concept vinyl turntable features small white cubes with small lead balls (2). They add weight and reduce mechanical vibrations and colourations. (3) The plinth of the Clearaudio Innovation turntables is made out of very hard and expensive wood: PanzerWood! It is even believed to be bulletproof…

Assembly phases of Clearaudio vinyl turntables

Once the parts have been machined, the elements have to be assembled together to obtain the end result.  (1) The base and plinth are not bonded. Clearaudio uses a special pressing method, that includes placing a very heavy weight on the stack of plinths to be assembled. (2) During this phase, the motor and DC power supply are assembled to the plinth of the Clearaudio Performance DC vinyl turntable. (3) Here is one of the cable specialists for Clearaudio’s vinyl turntable tonearms. Here, she is working on a Clearaudio Clarify tonearm.

(1) The base and plinth are not bonded. Clearaudio uses a special pressing method, that includes placing a very heavy weight on the stack of plinths to be assembled. (2) During this phase, the motor and DC power supply are assembled to the plinth of the Clearaudio Performance DC vinyl turntable. (3) Here is one of the cable specialists for Clearaudio’s vinyl turntable tonearms. Here, she is working on a Clearaudio Clarify tonearm.

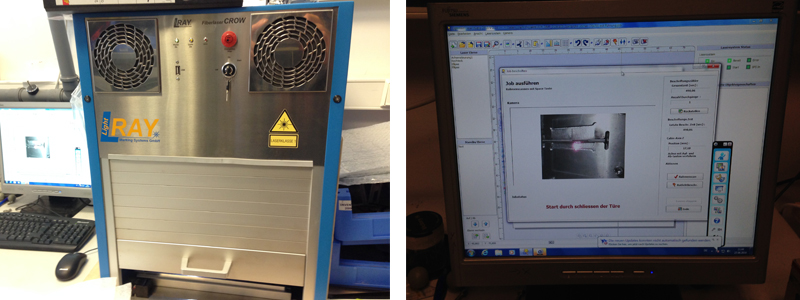

Etching of the name of the vinyl turntable

WithClearaudio, the markings on the vinyl turntable are not stickers! The manufacturer etches the information directly into the base of the turntable, using a digital etching machine.

Clearaudio product test phases

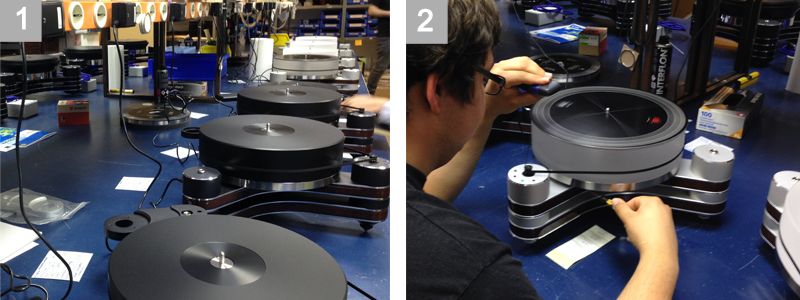

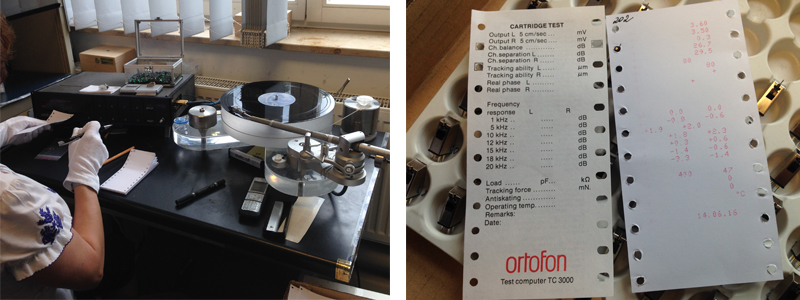

Naturally, between production and delivery, there is a test phase to check for the conformity of Clearaudio products. The turntables are tested in a special room in the plant (1). This photo features Clearaudio Innovation vinyl turntables during the test phase. During this phase, Clearaudio checks the motor and speed controller and machining conformity.  (2) This technician checks the speed using a record and a Clearaudio Speed Light stroboscopic lamp. He then adjusts the speed with the potentiometers via a small screwdriver underneath the platter. Clearaudio’s phono cartridges are also tested to optimise the sound quality. The principle is ‘simple’: the Hi-Fi cartridge is placed on a test record and an ‘Ortofon‘ spectrum analyser, that recovers the data that is then analysed by the technician. A voucher that summarises all the cartridge features is issued.

(2) This technician checks the speed using a record and a Clearaudio Speed Light stroboscopic lamp. He then adjusts the speed with the potentiometers via a small screwdriver underneath the platter. Clearaudio’s phono cartridges are also tested to optimise the sound quality. The principle is ‘simple’: the Hi-Fi cartridge is placed on a test record and an ‘Ortofon‘ spectrum analyser, that recovers the data that is then analysed by the technician. A voucher that summarises all the cartridge features is issued.

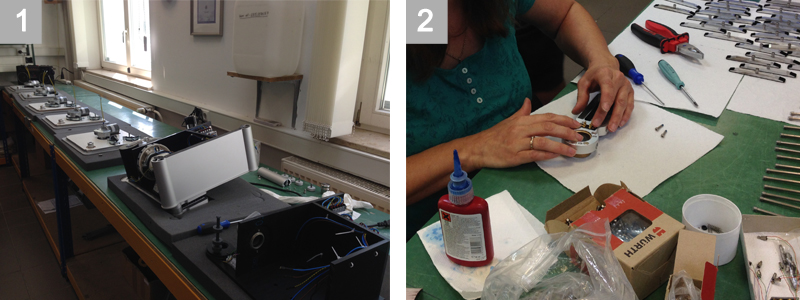

Production of Clearaudio record cleaning machines

Clearaudio is not only a manufacturer of vinyl turntables or phono cartridges. In fact, the German brand is also known to make great-quality record cleaners.  (1) A room is thus dedicated to the production of vinyl record cleaners. On this photo, you can see how the Smart Matrix Pro Silver is made. (2) This person is also in charge of assembling all the parts of the cleaning arm of the Clearaudio Double Matrix Pro Sonic record cleaner.

(1) A room is thus dedicated to the production of vinyl record cleaners. On this photo, you can see how the Smart Matrix Pro Silver is made. (2) This person is also in charge of assembling all the parts of the cleaning arm of the Clearaudio Double Matrix Pro Sonic record cleaner.

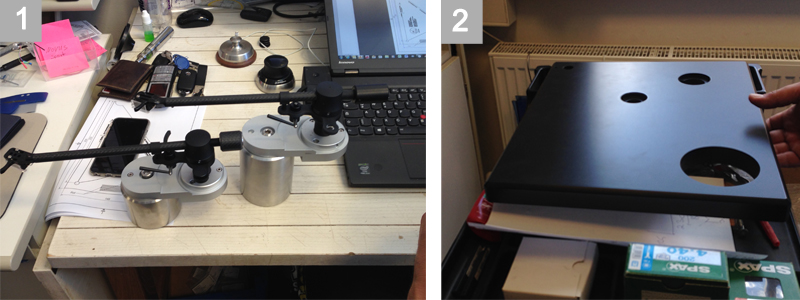

Design of Clearaudio’s new products

During our visit, we saw the Research & Development department, which is directly inside the Clearaudio plant. A room is thus fully dedicated to the development of the prototypes for the new products. We were also able to admire the prototype of the new Clearaudio tonearm (1), as well as the base of a new Clearaudio vinyl turntable (2). Coming up in 2017?!  The German brand Clearaudio actually showed us a few new products! New turntables will hit the market: the Innovation Basic and Performance DC Wood. Here is an overview.

The German brand Clearaudio actually showed us a few new products! New turntables will hit the market: the Innovation Basic and Performance DC Wood. Here is an overview.

Production of Mc Intosh vinyl turntables

Clearaudio has been making high-end McIntosh vinyl turntables for a few years already. We were shown to the room where these great MT5 vinyl turntables and MT-10 are made. It is rare to see so many in the same room!

*****

This visit was very educational and interesting, both technically and musically as well as for the human aspect! A great thank you to Robert Suchy and Jérôme and Philippe, the French importers for Hamy Sound, for their kindness and warm welcome!